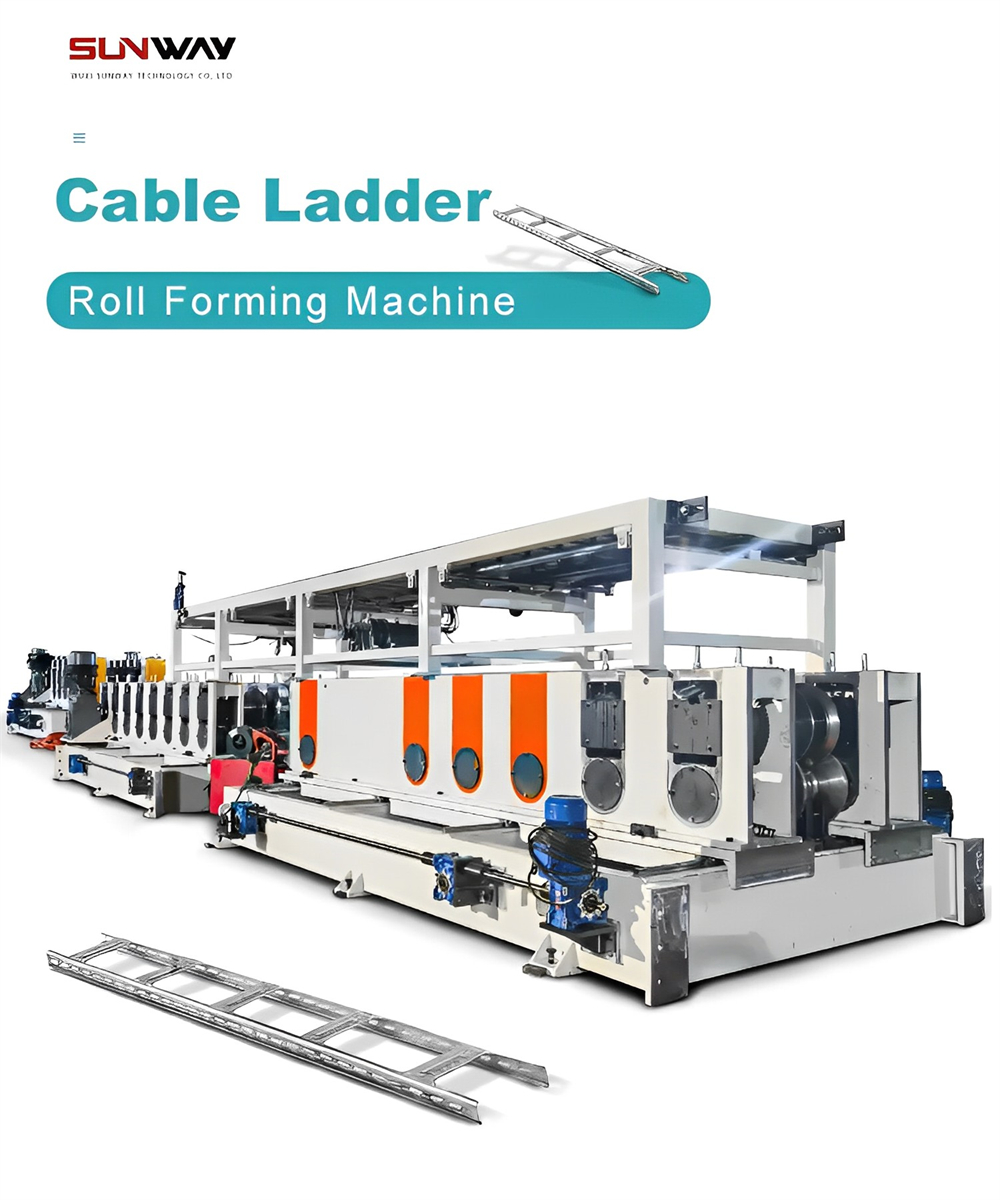

Cable Ladder roll forming machine also sometimes is called Ladder type Cable Tray roll forming machine. This line is commonly used to make different kinds of cable trays, which is widely used in electrical fields, decorations, industrial constructions etc.

This cable ladder roll forming line can produce 100mm to 300mm or more width cable trays and cable ladders with automatic width adjustment. Users only need to key in the width of the cable ladders, the roller stands can move in and out to adjust the gap between the rollers for various cable ladders widths. Main material can be used are cold / hot rolled steel coils with 1.0mm to 2.5mm thickness.

In Electrical & energy Industries, we are able to manufacture more related machines like Solar strut channel roll forming machine, DIN rail roll forming machine and Electrical Enclosure Box roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

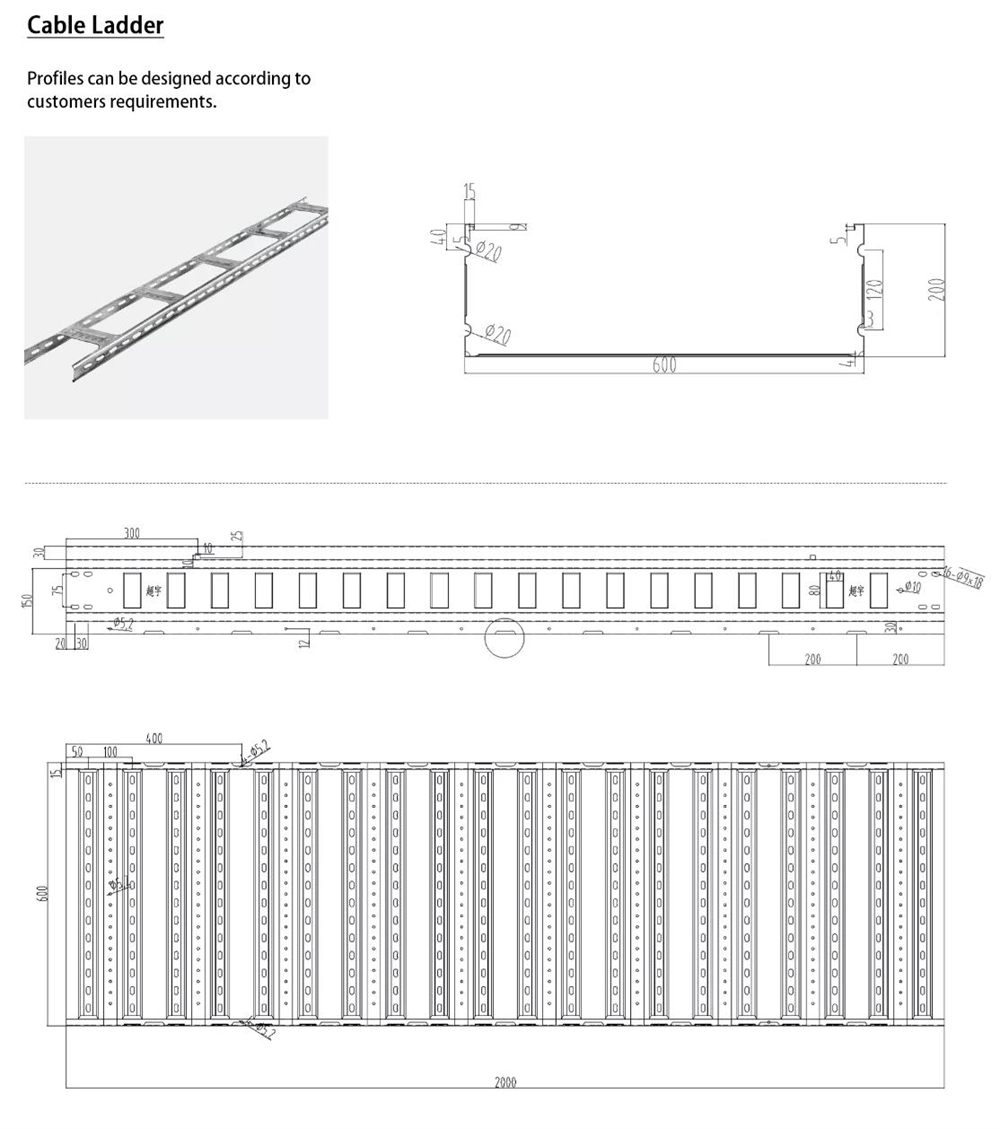

Cable Ladder Roll Forming Machine Profile Drawings

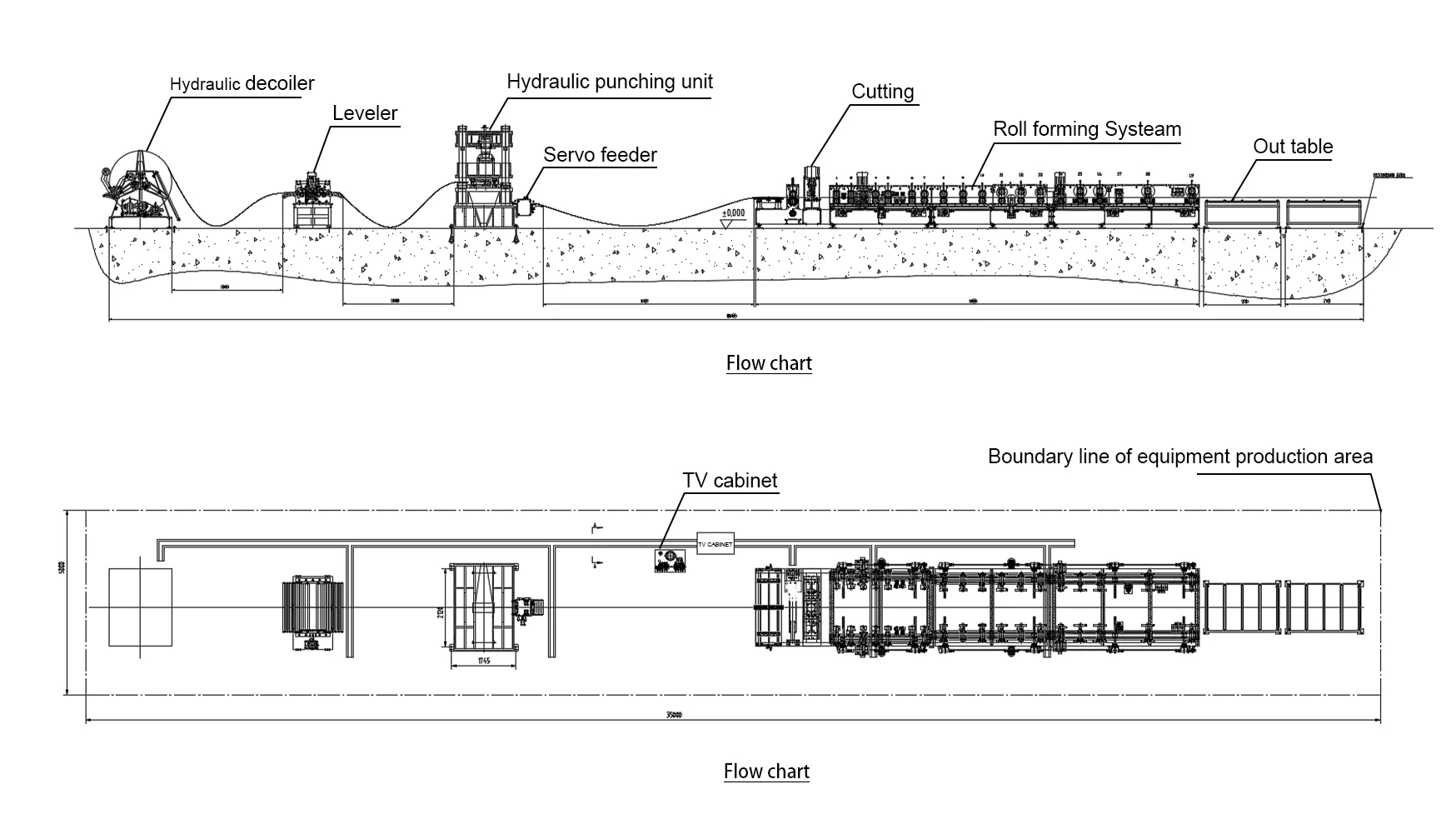

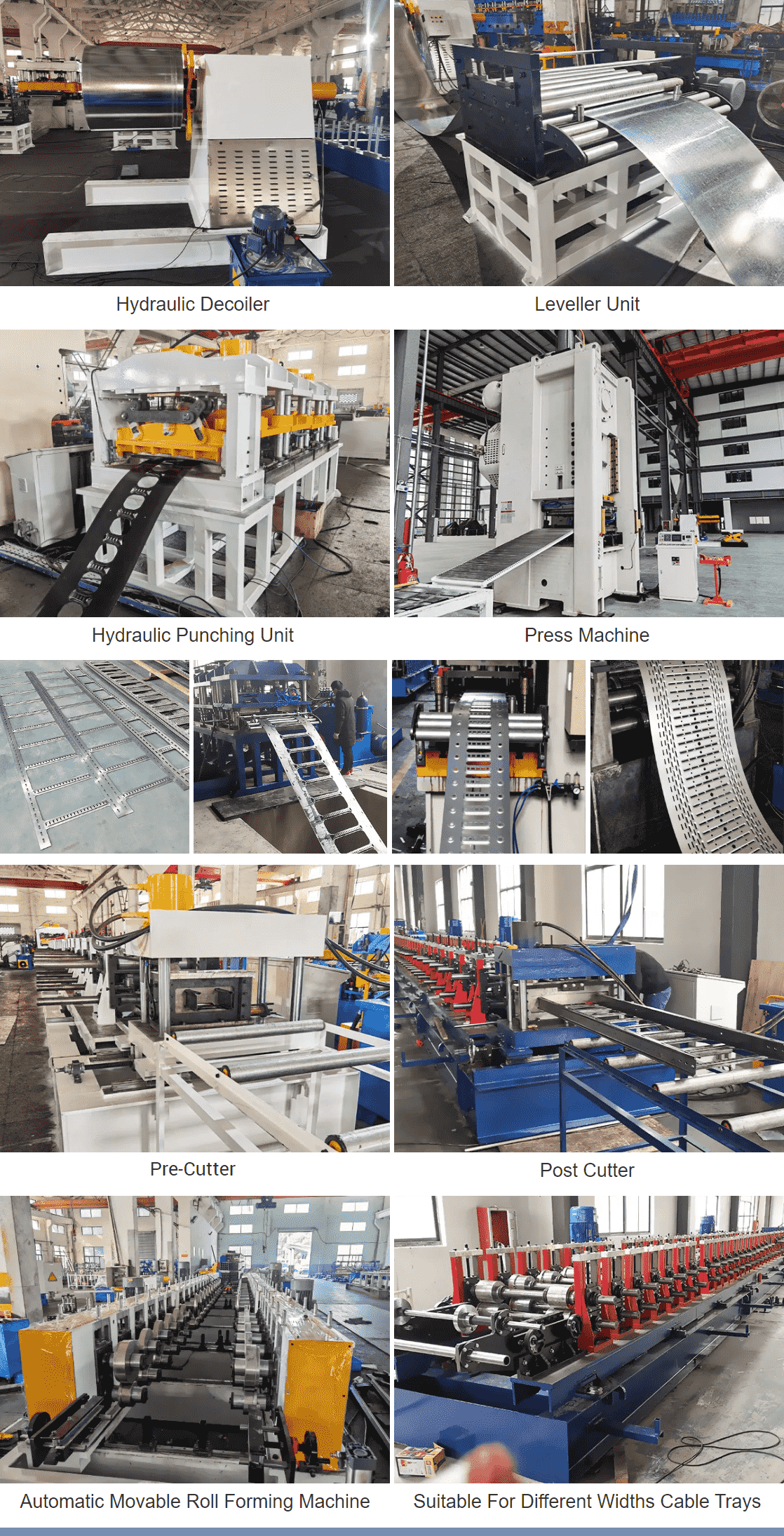

Cable Ladder Roll Forming Machine Production Line

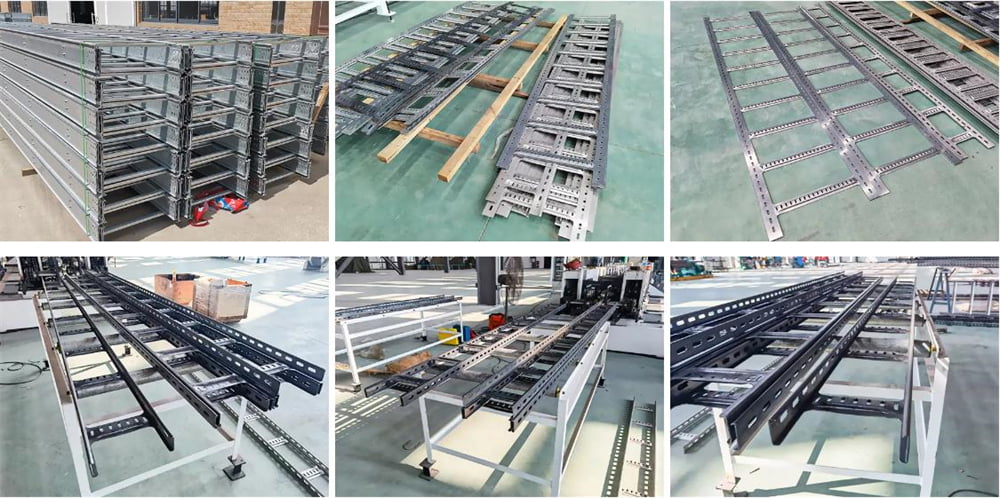

Cable Ladder Roll Forming Machine Details

Product Parameters

| Cable Tray Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Steel |

Thickness(MM): 0.6-1.2 or 1-2 even more

|

| B) PPGI | ||

| C) Carbon Steel | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Cable Tray Size | 50/100-600mm Or According To Profile Drawings | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Punching Press (Optional) |

| Forming Station | 20 | * According To Your Profile Drawings |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Cantilever Type Adjust The Width And Height Freely | * Forged Iron station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Profile Drawings |

| Rollers’ Material | GCr 15 | * Cr12Mov(Optional) |

| Cutting System | Post-cutting | * Pre-cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

A brief introduction to the cable tray roll forming machine

A cable tray roll forming machine is a specialized industrial machine used for the manufacturing of cable trays. Cable trays are support systems that provide a safe and organized way to route and manage electrical cables in various commercial and industrial settings.

The roll forming machine is designed to efficiently produce cable trays by continuously feeding a metal coil through a series of rollers and dies. The process involves shaping the metal into a specific profile that matches the design of the cable tray. The machine typically includes components such as decoilers, leveling units, roll forming stations, cutting mechanisms, and stacking systems.

Here is a brief overview of the key steps involved in the cable tray roll forming process:

- Coil Feeding: The machine starts by unwinding the metal coil from a decoiler. The coil is then fed into the machine using a feeding system.

- Leveling: To ensure a smooth and even material flow, leveling units are used to flatten the coil and remove any imperfections or deformations in the metal.

- Roll Forming: The metal passes through a series of roll forming stations, which consist of sets of rollers and dies. These rollers gradually shape the metal into the desired profile of the cable tray. The number of roll forming stations can vary based on the complexity of the cable tray design.

- Cutting: Once the cable tray profile is formed, the roll forming machine incorporates a cutting mechanism to trim the cable tray to the desired length. Various cutting methods can be used, such as hydraulic shearing or flying saws.

- Stacking and Packaging: After the cable tray sections are cut, they are stacked and arranged for further processing or packaging. Some roll forming machines may include an automated stacking system to improve productivity.

- Additional Processes: Depending on the specific requirements, the cable tray sections may undergo additional processes such as hole punching, bending, or surface treatment, which can be integrated into the roll forming machine or performed separately.

Cable tray roll forming machines offer several advantages, including high production efficiency, accuracy, and consistency in creating cable tray sections. They enable manufacturers to produce cable trays in various shapes, sizes, and configurations, catering to the specific needs of different industries.

It’s important to note that the exact design and capabilities of cable tray roll forming machines can vary among manufacturers, as they may incorporate different features and technologies to optimize the manufacturing process.

top 5 cable tray roll forming machine factory

- WUXI SUNWAY MACHINERY CO., LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

- Bradbury Group: The Bradbury Group is a global leader in roll forming and metal processing equipment. They offer a range of roll forming machines, including those for cable tray production.

- Samco Machinery: Samco Machinery is a renowned manufacturer of roll forming equipment with a diverse product portfolio. They have expertise in producing roll forming machines for various industries, including cable tray manufacturing.

- Yoder Manufacturing: Yoder Manufacturing has a long history of producing high-quality roll forming equipment. They provide custom roll forming solutions, and cable tray roll forming machines are among their offerings.

- Formtek Group: Formtek Group is a conglomerate of companies specializing in the design and manufacturing of roll forming equipment. They have a wide range of roll formers, and cable tray roll forming machines are part of their product lineup.

Why choose China cable tray roll forming machine?

- Cost-effectiveness: China is known for its competitive manufacturing costs, including the production of roll forming machines. Chinese manufacturers often offer competitive prices for their equipment, which can be beneficial for businesses looking to optimize their investment.

- Wide range of options: China has a vast industrial base and a large number of roll forming machine manufacturers. This means you have a wide range of options to choose from, allowing you to find a machine that matches your specific requirements in terms of capacity, features, and budget.

- Manufacturing expertise: China has developed significant expertise in manufacturing machinery and equipment, including roll forming machines. Many Chinese manufacturers have extensive experience in producing roll forming machines and have invested in advanced manufacturing technologies.

- Customization capabilities: Chinese manufacturers often have the ability to provide customized solutions to meet your specific needs. They can tailor the design, specifications, and features of the roll forming machine to match your requirements, ensuring that you get a machine that aligns with your production goals.

- Established supply chain: China has a well-established supply chain infrastructure that supports the manufacturing industry. This means that you can easily access raw materials, components, and spare parts for your roll forming machine, ensuring smooth operations and timely maintenance or repairs.

- Export-oriented market: Chinese manufacturers have extensive experience in exporting their products to various countries around the world. They are familiar with international standards and regulations, and many offer support for logistics, shipping, and after-sales service.

influence factors of cable tray roll forming machine price

The price of a cable tray roll forming machine can be influenced by various factors. Here are some key factors that can impact the pricing:

- Machine Specifications: The specifications of the roll forming machine, such as its capacity, complexity, and size, can affect the price. Machines with higher production capacity or advanced features may be priced higher due to the increased materials, components, and engineering required.

- Material and Components: The quality and type of materials used in the construction of the machine can affect its price. Machines built with high-quality materials and components may have a higher price tag. Additionally, if the machine requires specialized or custom components, it may also impact the overall cost.

- Customization and Features: Roll forming machines that offer customization options or additional features beyond the standard configuration may have a higher price. This can include features like automatic stacking, hole punching capabilities, computerized controls, or specific design requirements to meet unique customer needs.

- Brand and Reputation: Well-established and reputable brands in the roll forming industry may command higher prices due to their brand value, proven reliability, and after-sales support. Manufacturers with a strong track record and positive customer reviews often price their machines accordingly.

- Production Volume: The volume and frequency of machine production can affect pricing. Manufacturers that produce machines in large volumes may have more cost-efficient production processes, allowing them to offer more competitive prices. On the other hand, machines produced in smaller quantities or as custom orders may have a higher price to account for the unique production requirements.

- Market Competition: The competitive landscape within the roll forming machine market can influence prices. If there are numerous manufacturers offering similar machines, it can drive prices down due to increased competition. Conversely, if there are limited suppliers or specialized machines, prices may be higher.

- Additional Services and Support: After-sales services, such as warranty, technical support, installation, and training, can also impact the pricing. Machines that come with comprehensive support services or extended warranty coverage may have a higher upfront cost.

It’s important to note that these factors can vary among manufacturers and specific machine models. When comparing prices, it is crucial to consider the overall value, including the machine’s quality, performance, durability, and the reputation of the manufacturer.

Reviews

There are no reviews yet.