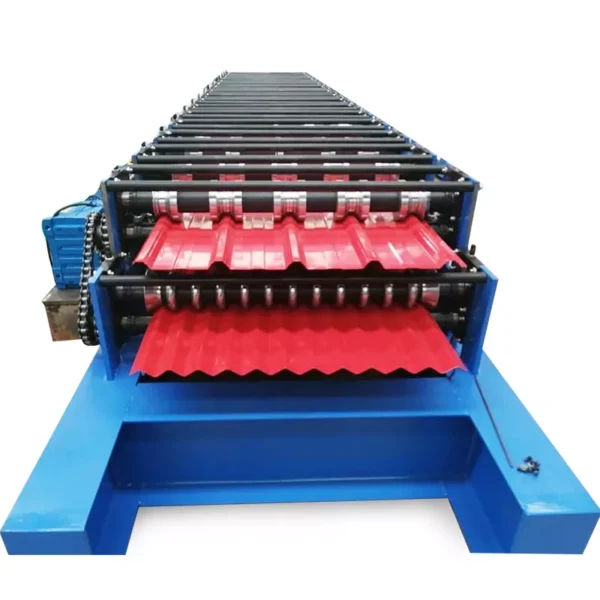

Double Layer Roll Forming Machine adopts steel coils as material and gets roofing sheets after the process of uncoiling, feeding, roll forming, cutting into length and output with table. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

Double Layer Roll Forming Machine Details

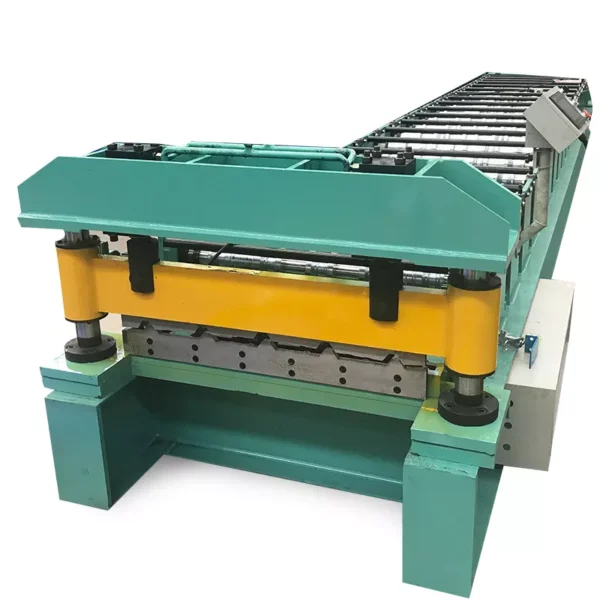

Stand Base

Select high quality steel as raw material with high strength and heavy duty, which has strong resistance to deformation.

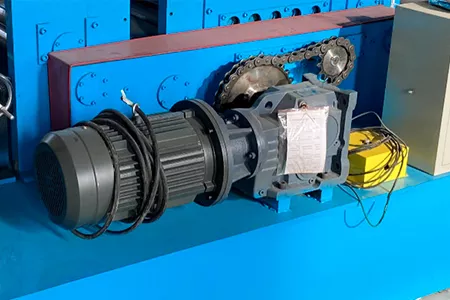

Motor

Adopt top brand motor for drive system, more stable and effective.

Rollers & Shafts

With many years of production experience, more professional and more precision.

Customization

Senior and experienced engineer control the whole process for your customize.

Double Layer Roll Forming Machine Parameters

| Product | Roof sheet roll forming machine |

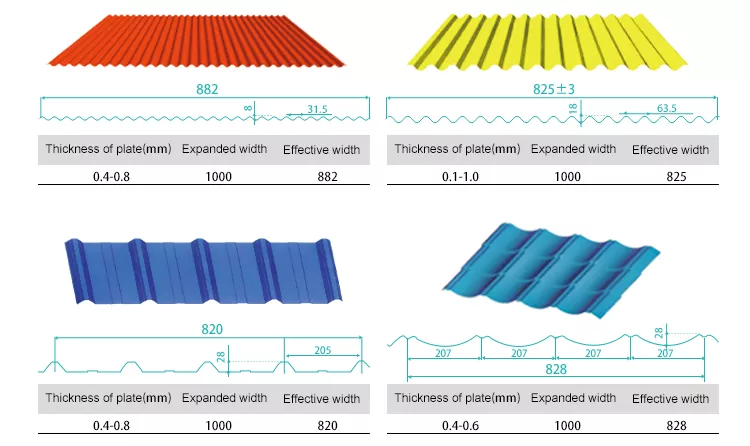

| Model | Corrugated Trapezoidal (Customizable ) |

| Base Material | GI/GL, PPGI/PPGL, Aluminum Coil |

| Thickness | 0.3mm-0.8mm |

| Effective Width |

600-1250mm (According To Customer Requirements /Customizable)

|

| Roller Station | 14-18 Stations |

| Roller Material | 45# Steel / Bearing Steel/ Cr12Mov |

| Roller Driven Type | By Chain/ Gearbox |

| Color |

According To Customer Requirements / Customizable

|

| Brand | SUNWAY |

| Control System |

Worldwide Famous Brand PLC (Panasonic, Siemens, Delta, etc)

|

| Power | 4KW-5.5KW-7.5KW |

| Frame | 350 H Steel / 400 H Steel |

| Cutting Drive | Hydraulic Drive |

| Cutting&Hydraulic Type |

Type:Double Guide Pillar Hydraulic Cutting.

Hydraulic Pump Station :4kw Blade:Cr12mov HRC:58-62 |

| Way Of Drive | 1.2 inch single chain |

Product Type

What is double layer roll forming machine?

A double layer roll forming machine is a specialized type of machinery used in the metalworking industry to produce two different profiles or layers of sheet metal simultaneously. It is a variation of the traditional roll forming process, which involves continuous bending of a long strip of metal through a series of rollers to achieve a desired shape.

The double layer roll forming machine consists of multiple sets of rollers, each set designed to produce a specific profile. The machine can accommodate two different sets of tooling, typically located on top of each other, allowing for the simultaneous forming of two different profiles. This enables the production of two different types of metal panels or sheets with varying shapes, dimensions, and configurations.

The process begins with feeding the sheet metal coil into the machine. The coil passes through a series of rollers, which gradually shape and bend the metal into the desired profiles. The upper set of rollers corresponds to the first layer, while the lower set of rollers corresponds to the second layer. The rollers are designed with specific contours and profiles to impart the desired shape to the metal as it passes through.

Double layer roll forming machines are commonly used in the construction industry for manufacturing roofing and wall cladding systems. By producing two layers simultaneously, the machine offers increased efficiency and productivity compared to traditional single-layer roll forming machines. It eliminates the need for separate machines or manual intervention to produce multiple profiles, resulting in time and cost savings.

Overall, the double layer roll forming machine is a versatile and efficient tool for producing a wide range of metal profiles with different shapes and dimensions, making it a valuable asset in the metalworking and construction sectors.

application of roofing sheet roll forming machine?

The roofing sheet roll forming machine is a specialized piece of equipment used in the manufacturing of various types of roofing sheets. It plays a crucial role in the production of high-quality roofing materials with precise dimensions and profiles. Here are some common applications of roofing sheet roll forming machines:

- Residential Roofing: Roll forming machines are extensively used in the production of roofing sheets for residential buildings. They can create profiles such as corrugated sheets, standing seam panels, and metal tiles. These roofing materials are durable, weather-resistant, and provide an aesthetically pleasing finish to residential structures.

- Commercial and Industrial Roofing: Roll forming machines are also used to manufacture roofing sheets for commercial and industrial buildings. These sheets are designed to withstand heavy loads, extreme weather conditions, and provide excellent insulation properties. They can produce large-scale panels or sheets with specific profiles to meet the requirements of commercial and industrial roofing applications.

- Agricultural Buildings: Roll formed roofing sheets find application in the agricultural sector for constructing barns, sheds, and other farm structures. These sheets are commonly made from galvanized steel or other corrosion-resistant materials to protect against environmental factors. They provide reliable protection for livestock, equipment, and crops.

- Architectural Roofing: Roll forming machines are utilized in the production of roofing materials for architectural projects that require unique and distinctive designs. They can create custom profiles, curves, and shapes to match the specific architectural requirements of buildings, such as domes, arches, and complex roof configurations.

- Roofing Accessories: In addition to roofing sheets, roll forming machines can also manufacture various roofing accessories. These include ridge caps, flashings, gutters, downspouts, and trim components. These accessories ensure proper installation, water drainage, and enhance the overall aesthetics of the roofing system.

The versatility of roofing sheet roll forming machines allows manufacturers to produce a wide range of roofing products for different applications. The machines can accommodate different materials, including steel, aluminum, copper, and coated alloys, providing flexibility in meeting diverse customer needs.

How about double layer roll forming machine price?

The price of a double layer roll forming machine can vary significantly depending on several factors. These factors include the machine’s specifications, features, quality, brand, and the region where it is being purchased. Additionally, market conditions and fluctuations in raw material costs can also impact the price.

Generally, double layer roll forming machines tend to be more expensive than single-layer machines due to their increased complexity and ability to produce multiple profiles simultaneously. The price range for a double layer roll forming machine can typically range from a few thousand dollars to tens of thousands of dollars.

It’s important to note that the price of the machine is not the only consideration. Other factors such as after-sales service, warranty, training, and support should also be taken into account when evaluating the overall value of the machine.

To get an accurate price for a double layer roll forming machine, it is recommended to contact manufacturers, suppliers, or distributors directly. They can provide detailed information about the specific machine models, customization options, and pricing details based on your specific requirements.

function of roofing sheet roll forming machine

The roofing sheet roll forming machine performs several functions in the production process of roofing sheets. Here are the key functions of a typical roofing sheet roll forming machine:

- Material Feeding: The machine is designed to handle a continuous strip or coil of raw material, typically metal, such as steel, aluminum, or copper. The material is fed into the machine, usually through a decoiler, which unwinds the coil and supplies it to the forming section.

- Roll Forming: The primary function of the machine is to shape the flat metal strip into a desired profile for the roofing sheet. This is achieved through a series of forming rollers or tooling sets, each responsible for bending and shaping the metal gradually. The rollers have specific contours and profiles that shape the metal according to the desired roofing profile, such as corrugated, standing seam, or metal tiles.

- Cutting: Once the desired profile is formed, the machine incorporates a cutting mechanism to trim the roofing sheet to the required length. Different cutting methods can be used, including mechanical shearing or hydraulic punching, depending on the machine design.

- Profile Embossing or Stamping: In some cases, the roofing sheet roll forming machine may have additional functions to add embossing or stamping patterns onto the sheet surface. This is often done to enhance the aesthetics or functionality of the roofing sheet, such as adding textures or improving water drainage.

- Control System: The machine is equipped with a control system that oversees the operation, monitoring various parameters such as speed, length, and position. The control system ensures precision and consistency throughout the roll forming process.

- Material Handling: The roofing sheet roll forming machine may include mechanisms for handling the finished sheets, such as stacking or packaging systems. These systems facilitate the efficient collection, stacking, and storage of the produced roofing sheets.

The roofing sheet roll forming machine combines these functions to produce high-quality roofing sheets in a continuous and automated process. It offers precision, speed, and efficiency in the manufacturing of roofing materials, meeting the requirements of various roofing applications in the construction industry.

Reviews

There are no reviews yet.