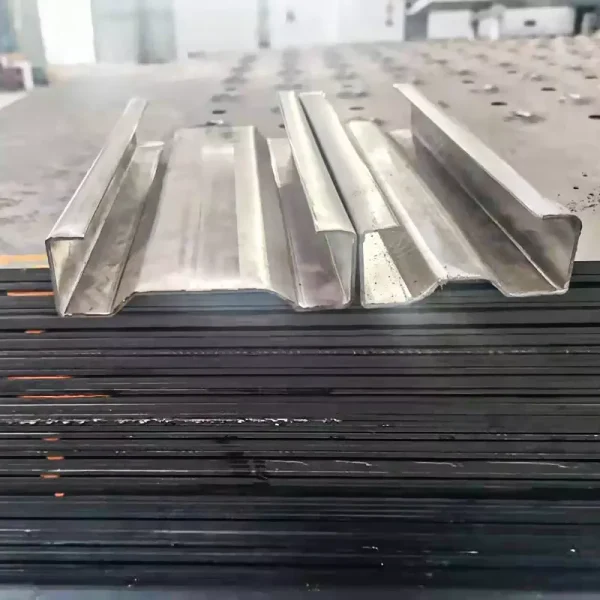

This Sigma purlin roll forming machine also named M Purlin Roll Forming Machine is used to produce M shape purlins from 80-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

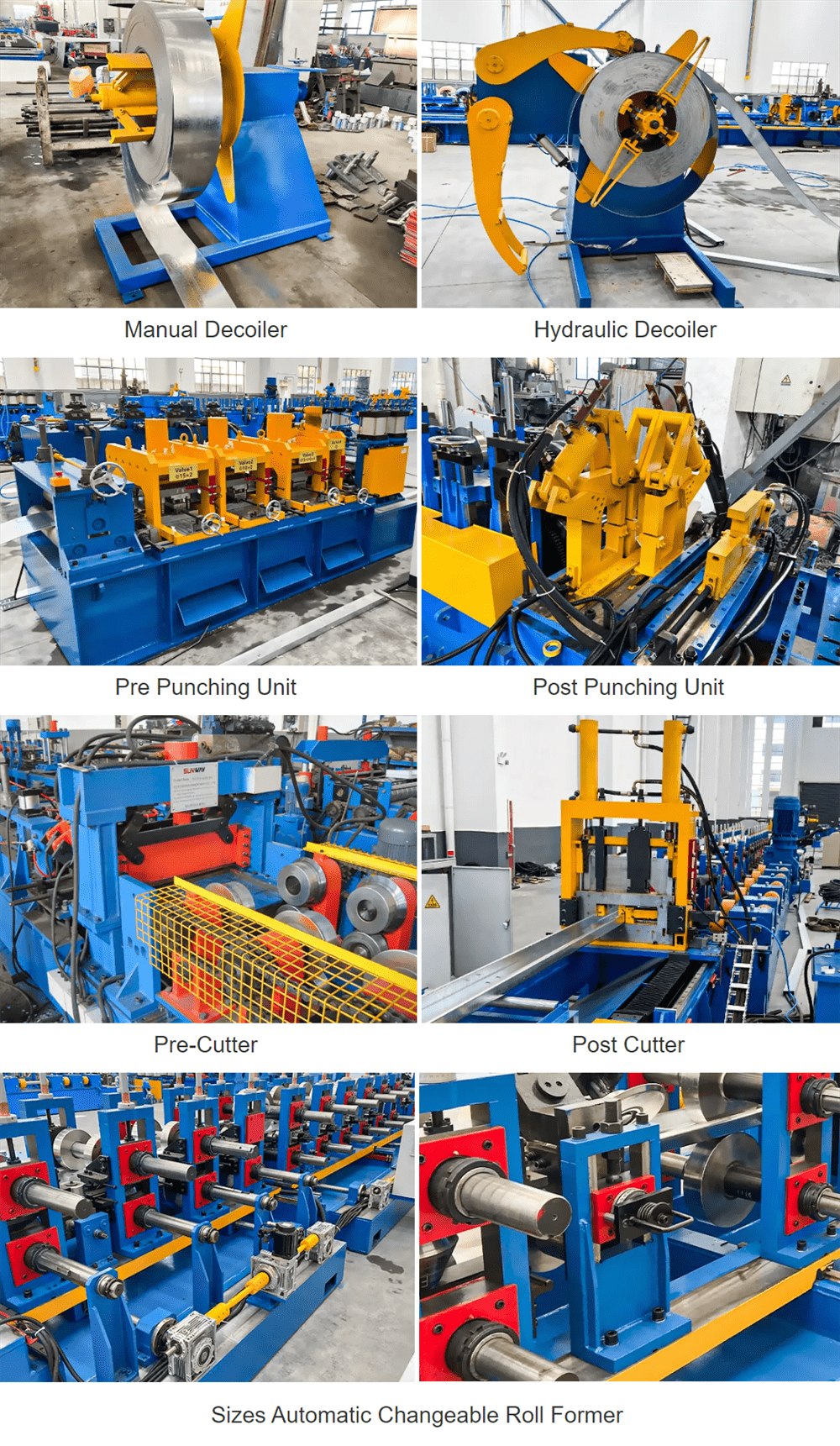

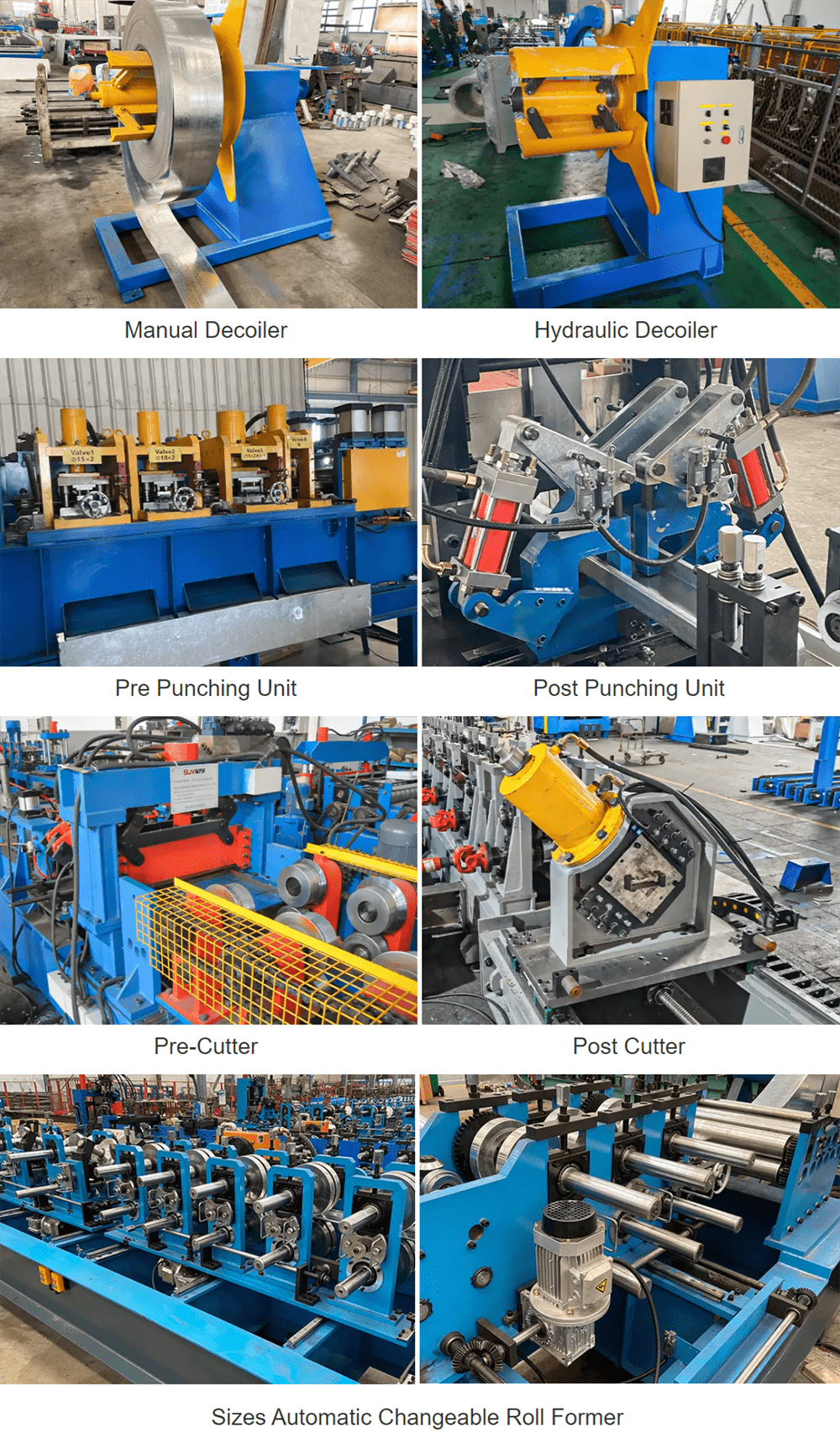

SUNWAY design this machine to work with any size of the purlin, automatically adjustable sizes by PLC or manually adjust handle wheel to change the sheet width to get different width and height. This is much more easily than adjust the spacers and can save more time. Regarding the punching unit, we can design pre punching, post punching according to your requirement. For cutting unit, you can choose the pre-cut or post-cut which is universal cutting. The driving system we adopt the chain and mostly with gimbal /gearbox for transmission if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

Purlin roll forming machine is the most popular and has an extensive use in Metal Building Systems, Huge Roofing Solutions, Construction and Renovation Projects etc. Our Purlin roll forming machine could produce C purlin, U purlin, Z purlin. According to your section profile, size range, thickness range we could provide you different solutions of purlin roll forming machine to manufacture a complete range of structual purlins (height and width change using automatic system by motors): If you only need to produce few sizes, we also suggest manually change sleeves, it’s more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Click here to learn more about the purlin roll forming machine

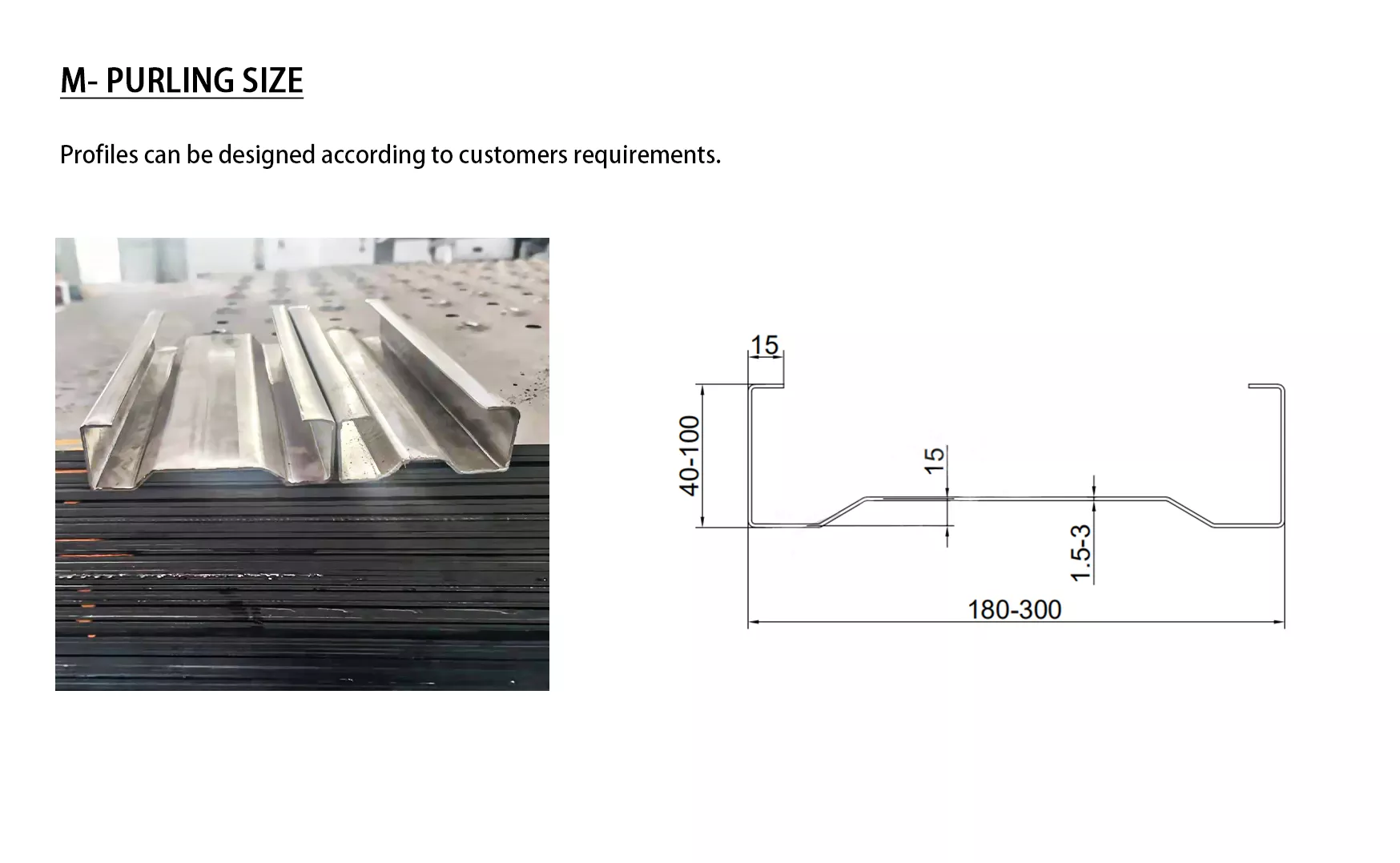

Profile Drawings

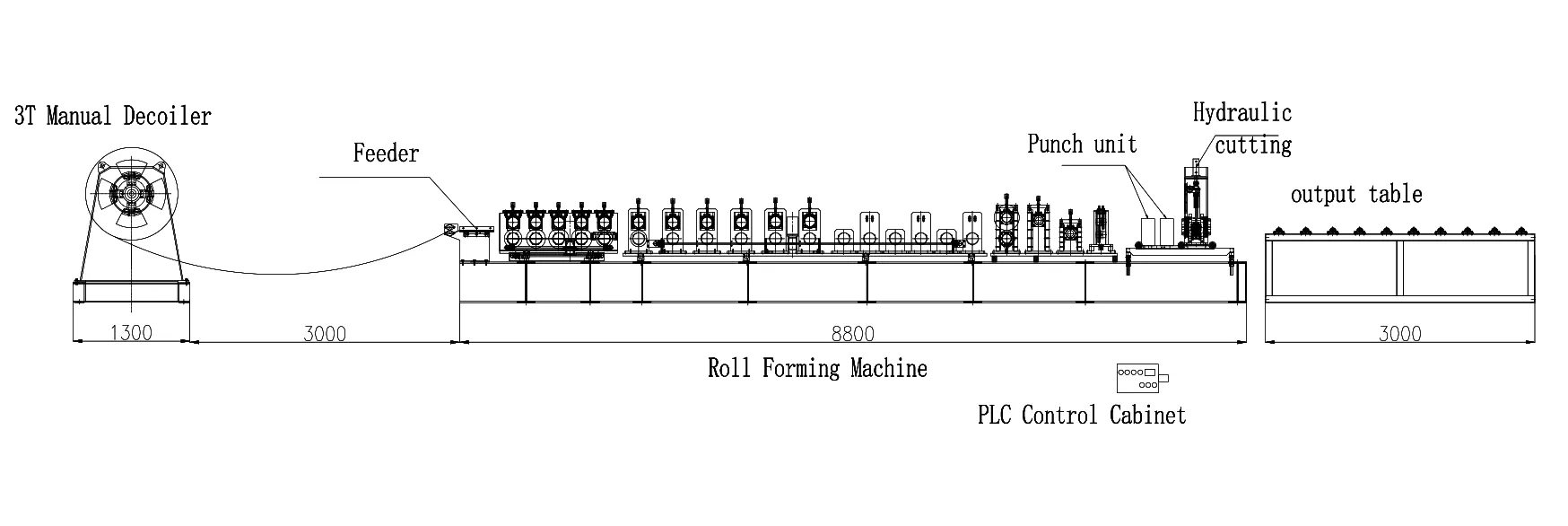

Production Line

Product Details

Product Parameters

| Auto Size Changeable Sigma Purlin Roll Forming Machine | ||

|

Machinable Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3 or as per customer

|

| B) Carbon Steel Coil | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G350 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station | * Pre-punch / Post Punch (Optional) |

| Forming Station | About 16 Stations | |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Forged Iron Station (Optional) |

| Forming Speed | 10-20 (M/MIN) | * Or According To Your Requirement |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Pre-cutting | * Post- universal Cutting (Optional) |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Application

What is automatic c purlin roll forming machine?

An automatic C purlin roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce C-shaped purlins. Purlins are structural components used in the construction of buildings, typically to support the roof or walls. C purlins have a C-shaped cross-section, resembling the letter “C.”

The roll forming machine is designed to automatically feed, shape, and cut metal coils into C-shaped purlins. It consists of a series of rollers and tooling stations that gradually shape the metal strip into the desired profile. The machine operates in a continuous process, with the metal strip being fed into the machine and transformed into a finished C purlin at the other end.

The automatic nature of the machine means that it requires minimal manual intervention. Once the machine is set up and configured with the desired parameters, it can produce C purlins consistently and efficiently. The machine can be programmed to produce purlins of different sizes and lengths by adjusting the settings.

Automatic C purlin roll forming machines are widely used in the construction industry due to their ability to produce purlins with high precision and speed. They offer advantages such as reduced labor costs, improved productivity, and consistent product quality.

advantages of oem c purlin roll forming machine

- Expertise and Quality: OEM manufacturers specialize in roll forming equipment and have extensive knowledge and experience in designing and producing high-quality machines. By opting for an OEM machine, you can benefit from their expertise and ensure that you are getting a reliable and well-built product.

- Customization: OEM machines can be tailored to meet your specific requirements. The OEM manufacturer will work closely with you to understand your needs and customize the machine accordingly. This ensures that the machine is optimized for your production process, allowing you to achieve the desired output and quality.

- Support and Training: OEM manufacturers often provide comprehensive support and training services. They can assist you in the installation, setup, and operation of the machine. Additionally, they can offer training to your staff, ensuring they are knowledgeable about the machine’s operation and maintenance. This support can help minimize downtime and maximize productivity.

- After-Sales Service: OEM manufacturers typically offer after-sales service and support. This includes assistance with troubleshooting, spare parts availability, and maintenance services. Having reliable after-sales support ensures that any issues or concerns you may have with the machine can be addressed promptly, minimizing disruptions to your production.

- Branding Opportunities: With an OEM machine, you have the flexibility to brand the machine under your company name or label. This allows you to enhance your brand visibility and establish your identity in the market. You can also market the machine as part of your product line, providing additional value to your customers.

- Cost-Effectiveness: Collaborating with an OEM manufacturer can often be a cost-effective solution compared to developing the equipment in-house. You can save on the expenses associated with research and development, engineering, and manufacturing facilities. Additionally, by partnering with an OEM manufacturer, you can leverage their economies of scale, potentially reducing the overall cost of the machine.

how about changeable u purlin roll forming machine work?

A changeable U purlin roll forming machine is a roll forming machine that is specifically designed to produce U-shaped purlins with changeable sizes. U purlins are commonly used in construction to provide structural support for roofs, walls, and floors.

The key feature of a changeable U purlin roll forming machine is its ability to produce U purlins of different sizes and dimensions. This flexibility allows for versatility in manufacturing, as the machine can be easily adjusted to produce U purlins of various widths, depths, and flange lengths.

Here’s how a changeable U purlin roll forming machine typically works:

- Material Feeding: The machine starts by feeding a coil of metal strip into the machine. The strip is usually made of galvanized steel, stainless steel, or other suitable materials.

- Roll Forming: The metal strip passes through a series of rollers and tooling stations that gradually shape it into a U-shaped profile. These rollers and stations are adjustable, allowing for changes in the width and depth of the U purlin being produced.

- Cutting and Length Measurement: Once the U-shaped profile is formed, the machine includes a cutting mechanism that cuts the purlin to the desired length. Some machines also have an integrated length measurement system to ensure accurate and consistent cutting.

- Stacking or Packaging: After cutting, the finished U purlins are typically stacked or packaged for easy handling and transportation.

The changeable nature of the machine enables quick and efficient switching between different U purlin sizes. The adjustments are typically made through simple manual or automated controls, allowing operators to set the desired dimensions easily.

Reviews

There are no reviews yet.